| Case Name |

Fire of toluene during use with placing a toluene vessel near the ignition source at a joint sheet manufacturing process |

| Pictograph |

|

| Date |

April 14, 1989 |

| Place |

Nishiyatsushiro county, Yamanashi, Japan |

| Location |

Auto parts factory |

| Overview |

On April 14th, 1989. A fire occurred in a factory manufacturing joint sheets used in automobiles. The fire started at the lower part of a plate manufacturing roller, a toluene storage container caught fire, and a plate manufacturing machine was damaged by the fire. The cause of the fire was not clarified. There was no specific cause. The toluene storage container was located near the plate manufacturing machine in which sparks were generated. Basic safety knowledge of handling flammable dangerous materials was lacking. |

| Incident |

A fire started from the lower part of a plate manufacturing roller, a toluene storage tank caught fire, and a plate production machine was damaged by the fire. The plate is used for a part of an automobile. |

| Processing |

Consumption and usage |

| Individual Process |

Other |

| Substance |

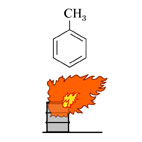

Toluene, Fig2 |

| Type of Accident |

Fire |

| Sequence |

08:00 on April 14th, 1989. Joint sheet plate manufacturing work started. The workers operated the joint sheet plate production machine on one-hour shifts (routine work).

About 16:52. A fire started at the lower part of the plate manufacturing roller, a toluene storage tank caught fire, and a plate manufacturing machine was damaged by the fire. |

| Cause |

Toluene vapor used for the joint sheet plate manufacturing machine formed a combustible mixture on the floor near the plate manufacturing machine. Although the ignition source has not been specified, the following causes have been considered.

1. Sparks at a pressure-switching switch.

2. A tin conduit at the left side of the machine contacted the roller and a spark occurred.

3. Electrification of workers.

A toluene storage container located near the plate manufacturing machine, in which a spark might be generated. The basic safety knowledge of handling flammable dangerous materials was lacking. |

| Response |

Ten workers nearby carried out initial fire fighting with fire extinguishers. |

| Countermeasures |

The toluene storage container was removed and toluene was charged by pipe transfer. An improvement in the factory building is being attempted according to the fire protection law.

An outdoor fireplug had been installed near the location of the fire, but, it was of no use for an oil fire. In a factory handling dangerous materials, preparation of fire foam and a foaming nozzle etc, is required by voluntarily. |

| Knowledge Comment |

The fire occurred because the storage tank for a flammable dangerous material such as toluene was mounted near the plate manufacturing machine, in which a spark might be generated. The storage tank for a dangerous material should be put in a safe place. |

| Background |

The problem must be inadequate management. There was no knowledge of handling dangerous materials, and safety education might not have been carried out either. The facilities were also insufficient. |

| Reason for Adding to DB |

Example of fire caused due to inadequate management of combustible dangerous substances (toluene) |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Organizational Problems, Inflexible Management Structure, Insufficient Education/Training, Ignorance, Insufficient Knowledge, Convincement, Malicious Act, Rule Violation, Act Violation, Planning and Design, Poor Planning, Poor Design, Secondary Damage, External Damage, Fire, Bodily Harm, Injury, Loss to Organization, Economic Loss, Direct Monetary Damage 34 million yen

|

|

| Sources |

Fire and Disaster Management Agency. Major cases of accidents. Fire in joint sheet manufacturing process during use of toluene. Accident cases of dangerous materials. pp.31,372-373

|

| Number of Injuries |

1 |

| Physical Damage |

A joint sheet manufacturing roller, an automated painting machine and a conveyor, etc. were damaged by fire. Toluene burned. |

| Financial Cost |

¥ 34 million (Accident cases of dangerous materials) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

DOBASHI, Ritsu (School of Engineering, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|