| Case Name |

Fire of hexene-1 in the piping of a hydrocarbon vapor recovery unit (VRU) at a tank lorry filling station |

| Pictograph |

|

| Date |

February 18, 2000 |

| Place |

Kawasaki, Kanagawa, Japan |

| Location |

Oil terminal |

| Overview |

A fire occurred at a lorry station of a tank leasing company. The filling area had hydrocarbon vapor recovery facilities (VRU), which recovered vapor generated on loading to lorries. Filling the tank lorry started under the condition in which the bypass valve connecting the lorry inlet and VRU directly was open, and the loading main valve to tank lorry was closed. Therefore, hexene-1 being loaded went through the bypass valve, leaked from the suction port of VRU, was ignited by the engine of a nearby forklift, and a fire occurred. In addition, the hose was cut off because the lorry was hurriedly driven away without detaching the hose. The fire spread further for hexane-1 leaked from the cut hose, and around the loading valve at the left side of the tank lorry also burned. |

| Incident |

A fire occurred at a lorry station in a dangerous material tank leasing company. Liquid hexene-1 leaked from vapor piping of hydrocarbon VRU in the tank farm. The tank lorry driver pushed the emergency cut-off button. Leaking hexene-1 caught fire at a forklift nearby, which had stopped just under the lorry, and the forklift and part of the lorry station were damaged by a fire. In addition, the tank lorry operator drove the tank lorry away hurriedly. Therefore, a connected filling hose and a hydrocarbon vapor recovery hose were broken near the tank lorry connection, and hexene-1 started to burn. External walls of two buildings near the place where the tank lorry stopped were damaged by the fire when the tank lorry burned. |

| Processing |

Storage |

| Substance |

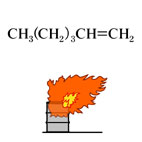

Hexene-1, Fig2 |

| Type of Accident |

Leakage, fire |

| Sequence |

On February 18th, 2000, at about 12:45. The tank lorry which caused the accident entered the lorry station.

About 14:40. At the lorry station No.1 spot, filling of hexene-1 to the lorry started.

About 14:45. About 1.7 KL had been filled. At that time, liquid hexene-1 leaked from vapor piping of hydrocarbon VRU in the tank farm. The tank lorry operator pushed the emergency cut-off button. Leaking hexene-1 caught fire near a forklift, which had stopped just under the lorry.

About 14:47. The tank lorry driver hurriedly drove the tank lorry away. Therefore, a connected filling hose and a hydrocarbon vapor recovery hose were broken near the tank lorry connection, and leaking hexene-1 started to burn. The tank lorry was driven about 30 m while burning, and stopped near the front doorway (in front of two office buildings). Fire extinguishing for the forklift was carried out with powder fire extinguishers by six private firemen.

About 14:48. Fire extinguishing for the tank lorry was carried out with powder fire extinguishers by ten private firemen. In addition, hoses from two fireplugs were extended, and water showering was carried onto the forklift. |

| Cause |

1. The lorry driver started the filling work of hexene-1 without closing the bypass valve. The hexene-1 passed through the bypass valve, flowed into the hydrocarbon VRU piping, and leaked from the suction port of the VRU.

2. The forklift, whose engine was idling, parked at the location of the leak. A fire was started by electrical sparks or the hot surface in the engine compartment.

3. Two hoses were cut off because the lorry was hurriedly moved without detaching them. The fire spread further by leaked hexene-1 from the cut hose. |

| Countermeasures |

1. A safety supervisor must be watching at lorry filling work. Another supervisor should be added in the early morning when many lorries arrive together.

2. Improvement of safety education. Training and education for transportation members including sub-contractors are carried out two times a year, and on hexene-1 filling work, a meeting between lorry station operators and transportation staff is held one time a month..

3. Installing the shipping monitor warning lamp so that forklifts do not enter the station.

4. Revising an operation manual and a check sheet.

5. Making the drivers put a display board on the windshield so that supervisors can notice.

6. Installing equipment with a warning light and a buzzer in the tank lorry, which operate when the bypass valve of the tank lorry is open. |

| Knowledge Comment |

A fire occurred due to failure by the lorry driver, and the fire spread because the lorry was moved with the filling hose still connected. It is necessary to complete the education of the filling operator and arrange an observer. Completeness of safety management is needed. |

| Background |

Habituation of the operation or miss-operating was the largest cause, which is judged from the following: the driver started the filling work with the bypass valve open and without opening the main valve, and a forklift with a gasoline engine was parked near the lorry station.

A fire expanded because the driver hurriedly drove the lorry away with the hose still attached. |

| Incidental Discussion |

It is necessary to install a flame arrester at the exhaust pipe of an automobile that approaches a place where dangerous materials are handled to prevent ignition. Use of forklifts with explosion-proof batteries is also desirable. |

| Reason for Adding to DB |

Example of fire at a tank lorry filling station |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Slackness of Management, Carelessness, Insufficient Precaution, Carelessness of Operator, Poor Value Perception, Poor Safety Awareness, Insufficient Recognition of Risk, Regular Operation, Erroneous Operation, Opening Different Valve without Consciousness, Secondary Damage, External Damage, Fire, Bodily Harm, Injury, 2 person injured, Loss to Organization, Economic Loss, Direct Monetary Damage 5 million yen

|

|

| Sources |

Kawasaki City Fire fighting station. Prevention division. Peace section. Fire at Tank lorry station. Material of the Kawasaki City complex safety countermeasures committee. (2000)

|

| Number of Injuries |

2 |

| Physical Damage |

Eight pipes for transferring dangerous materials were damaged by fire. A lorry station and one forklift were damaged by fire. External walls of two buildings were damaged by fire. |

| Financial Cost |

¥ 5 million (Material of the Kawasaki City complex safety countermeasures committee) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

DOBASHI, Ritsu (School of Engineering, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|