|

01. |

Organizational Problems |

|

02. |

Poor Management |

|

03. |

Looseness of Discipline |

|

04. |

Ignorance of Procedure |

|

05. |

Disregard of Procedure |

|

06. |

Omission of Confirmation |

|

07. |

Poor Value Perception |

|

08. |

Poor Safety Awareness |

|

09. |

Inadequate Risk Recognition |

|

10. |

Planning and Design |

|

11. |

Poor Planning |

|

12. |

No Consideration on Safety Engineering |

|

13. |

Malicious Act |

|

14. |

Rule Violation |

|

15. |

Safety Rule Violation |

|

16. |

Bad Event |

|

17. |

Chemical Phenomenon |

|

18. |

Abnormal Reaction |

|

19. |

Failure |

|

20. |

Large-Scale Damage |

|

21. |

Rapture |

|

22. |

Loss to Organization |

|

23. |

Economic Loss |

|

24. |

Manetary Damage 100 million yen |

|

|

|

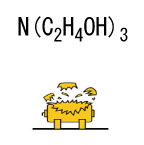

Rupture of a triethanolamine tank caused due to an erroneous injection of nitric acid

|

|

Knowledge Comment: |

|

For the nozzle connction at the lorry station, there are triple mistake; bad arrangement of location of nozzles, mis-connection by the driver who was the first time there and no confirmation of the valve operation. |

|

|

|

|