| Case Name |

A coating facility got burnt in warehouse construction. |

| Pictograph |

|

| Date |

March |

| Location |

In a plant |

| Overview |

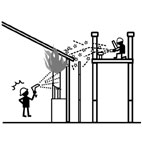

In a ward of Tokyo, during the construction of a warehouse next to the existing one , spark from welding work fell to a coating facility working ,and it got fire.

On that day, it was snowy. So at the morning meeting, responsible person of contractor advised to stop working, and that was decided.But after that, workers of iron frame had come to the place, the responsible person paid some "kindness"to them,and let them start the work. Though the responsible person did not understand the real cercumstances of the inside of the plant covered with sheets,he let them start the welding work with dogmatic decision. This is the diret reason of the disaster.

In welding works, sparks fly, and they go through many kind of spaces, and let combustibles burn. And it is known that it smolder calmly for hours and suddenly start to burn.The persons of plant side would have perfect counter measures for them and the contractors.

Process, working order , the change of them have to be decided under the central players.

What is happier, primary fire fighting succeeded, so this case did not get a serious , but it is possible if we do not obey the rules , we could be involved in severe danger at the building work. |

| Incident |

In a ward of Tokyo, during the construction of a warehouse next to the existing one , spark from welding work fell to a coating facility working ,and it got fire. |

| Sequence |

At 8am,of the accident day, the responsible person of orderer (Orderer), and the responsible person of contractor (Contractor)had regular meeting.The Contractor advised that " it is snowy , so concerning the contents of the work, we want to stop today's work."And this was okayed. Generally, in this meeting ,it was fixed that a responsible person of the worker who was on a production line close to the work have to join the meeting, and check if the production facilities work or not and fix the safety counter measure, and check the circumstance of execution of that.

Around 10am, the Contractor was informed that a fire broke out due to the work at the office.He told that works were not executed so the work was not the cause of the fire.But he went out to check the place where the coating facility was installed.

The coating facility was ,to spray some long materials(5.5m to 12m) moving on the roller conveyer in the booth(width 1m, height 1.5m,depth 3m), and some combustibles were used for the spray. the materials to coat on the conveyer was placed at about 1.3m height from the floor.

There was a ventilation pipe, and a pit more than 1m 's depth was digged bigger than the area of the booth on the ground.Because of the characteristics of the facilities, some coating compounds sticked inside the pit.

Sparks went into this pit, and a fire broke out in it ,and following, the booth, and the ventilation pipe were also got in the fire. |

| Cause |

In the meeting of the accident day's morning, the contractor advised the stop of the work and it was fixed, but workers of iron frames had come after this.The contracter pay kindness to the workers because the workers could not get paid if they did not work, and the snow was little, so he let them work.The reason why he did not inform about this decision , are i) He was afraid that the orderer would not permit this decision because of the danger of the work on the iron flames ii)He decided to stop the work if the snow get stronger.iii) Though he did not grasp the real circumstances of the inside of the production line, he thought that this work was not dangerous with dogmatic decision. iv) After the decision to stop the work , maybe the orderer would not come to see the work. so he had some regret but let them work. He said afterward. |

| Response |

Workers close the work plase did the primary fire fighting and got the fire down. Because of the fast and early fire fighting, after the fire got down, some cleaning and repair was done, then the stop of the coating work was no more than a half day.

The burnable materials were, coating materials, hoses,and pumps. If the primary fire fighting was not done, iron plates woud be melted, the repair work would cost a few days. |

| Countermeasures |

This is the failure case that makes us recongnize again that the changes of orde , process, and contents of work have to done under the permission of the central player.In this case, the contractor let workers begin welding work without checking the circumstance inside the plant.

In welding works, sparks fly, and they go through many kind of spaces, and let combustibles burn. And it is known that it smolder calmly for hours and suddenly start to burn.For the safety of the work close to dangerous materials, the plant side workers have to check the sheets ( width, length, coverage etc.) and add the sheet,and put weights on them to prevent to fly. And to put fire manager and so on, advise contractor some counter measures.

What is happy, the primary fire fighting succeeded so this case did not get severe one. But neglecting the rules fixed,then severe damage would come. |

| Knowledge Comment |

the changes of order , process, and contents of work have to done under the permission of the central player. |

| Reason for Adding to DB |

The safety of the work is confirmed by the cooperation of all the workers of the work.

the changes of order , process, and contents of work have to done under the permission of the central player. |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Ignorance, Insufficient Knowledge, Ignorance, Insufficient Knowledge, Malicious Act, Rule Violation, Regular Movement, Wrong Movement, Malicious Act, Rule Violation, Failure, Fracture/Damage, Loss to Organization, Social Loss, Damage to Society, Social Systems Failure

|

|

| Field |

Civil Engineering

|

| Author |

WATANABE, Tsunemi (Kochi University of Technology)

|

|