| Case Name |

The result in the execution of urgent local road development project which the mortar spray structure has not achieved the purpose of the construction since it was remarkably different from the construction design. |

| Pictograph |

|

| Date |

1991 |

| Place |

The Hienuki District Ohasama town in Iwate Prefecture. |

| Location |

The construction field. |

| Overview |

On the road improvement, since the construction of the mortar spray structure was remarkably different from the design, large number of cracks were generated in the slope constructed in the mortar spray structure. Therefore, government subsidy equivalent \ 3110,400 which concerned this construction was considered unreasonable without achieving the purpose. |

| Incident |

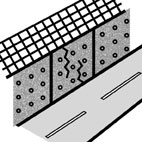

Mortar spray structure of 921.9m2 in this project had been decided to be constructed as following after the slope is cleaned, acording to the drawing and specification.

(a) Lay rhombic wire gauze ( the mesh 5 cm X 5 cm ) entire the slope in order to reinforce the mortar spraying layer. Wire gauze is supported and is fixed using anchor pin and spacer in 180 places per 100 m2 in order to be located in almost the center in the mortar spraying layer.

(b) Blow mortar using the compressed air in thickness of 10 cm, confirming the thickness of sprayed mortar using checking pin installed on the slope at right angle. Allowed smallest spraying thickness ( of the following "tolerance" ) is 8 cm, average spraying thickness is over 10 cm in the inspecting standard.

(c) Splattered materials that it did not adhere to spraying position and flew in the circumference are removed so that it may not harm the adhesion of the mortar.

However, when the slope constructed in the mortar spray structure was checked, large number of cracks were found. When the slope of 921.9m2 was investigated by drilling totals 113 places, situation as following was found on 72 places in 590.4m2.

(a) There were 52 places ( average spraying thickness 6.0 centi ) where the spraying thickness of the mortar was under 8 cm of the tolerance, and one was remarkably insufficient which was 3.6 cm.

(b) There were 21 places where the mortar had not adhered to the ground because of splattered materials remaining between ground and mortar spraying layer.

(c) There were 36 places where the wire gauze adhered in the ground directly. |

| Sequence |

The assistant industry which implemented earthwork, subbase course construction, mortars spray construction, etc. was carried out for road improvement at \ 34108,450( government subsidies \ 20465,070 ) construction expenses.

In the construction of the mortar spray structure, the confirmation of the spraying thickness was insufficient, and the construction was crude that splattered materials was not removed sufficiently and the mortar was sprayed without returning the wire gauze which adhered in the ground to the correct position.

Large number of cracks were generated on the slope constructed with the mortar spray structure.

Government subsidy equivalent \ 3110,400 which concerned this construction was considered unreasonable without achieving the purpose. |

| Cause |

Three following causes are considered. The first is the technical capability shortage of the builder of the site, because the spraying thickness of the mortar is remarkably insufficient. Next, the simple error has been committed by the looseness of the mind of the builder. Finally, it seems to be also one of the factors in which this phenomenon arose that such error was not be found, by the looseness of the management in the site. |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Staff, Organizational Problems, Poor Management, Malicious Act, Ethics Violation, Failure, Fracture/Damage

|

|

| Sources |

The 1992 fiscal year settlement inspection report ( Board of Audit ).

|

| Financial Cost |

Government subsidy delivery amount considered unreasonable \ 3110,400. |

| Multimedia Files |

Fig2.Construction concept chart

|

| Field |

Civil Engineering

|

| Author |

MIYAKI, Yuya (The University of Tokyo)

KUNISHIMA, Masahiko (The University of Tokyo)

|

|