| Case Name |

A single strand which had been tensioned busted out. |

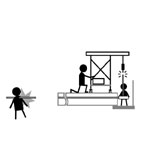

| Pictograph |

|

| Date |

July 10, 1995 |

| Place |

Fukushima Prefecture. |

| Location |

The construction site of the pre-stressed concrete bridge. |

| Overview |

When the 39th transverse pre-stressing single strand of 43 cables (φ21.8, tensile weight 57 tons, weight 24.8 kg/cable) was almost tensioned to the fix level, the inner wedge of the tension jack which held the single strand suddenly tripped. Then, the single strand and the fixture flew in the opposite direction to the tensioning. This single strand hit the clavicle of other company's worker who engaged in stonework of bank protection work 11m away from the bridge, and he died. |

| Incident |

At 1:55 pm on July 10th, 1995, at the construction site of the pre-stressed concrete bridge, during tensioning of the transverse pre-stressing single strand, the single strand flew and hit the other company's worker who worked 11m away from the bridge, and he died. |

| Sequence |

* The PC steel, which is used for pre-stressed concrete and has line type and rod type, was ordered shorter than it should have been.

* During tensioning, the single strand flew in the opposite direction to tensioning.

* There was a protective board at the tensioning side but not at the fixed side.

* The single strand hit the other company's worker who worked 11m away from the bridge, and he died. |

| Cause |

* A staff of main contractor had ordered a short one and the site worker tensioned this short PC steel.

* During tensioning, the wedge was set at the improper position. (Since the wedge in the jack was set near the edge of the strand, the strand worked loose and slid.

* The tensioning was operated without a protective board at the fixed side. (A direct factor)

* The fundamental cause was a lack of the operation management. |

| Response |

PC steels were changed to 20-centimeters longer ones and stressed. |

| Countermeasures |

* The staffs should order the proper length PC steels.

* The operators should check the surplus length of the strand after setting the fixture of the strand.

* The operators should start stressing after checking that the proper length of the surplus strand pokes out from the jack after setting the jack.

* After finishing stressing and loosing the jack, the operators should check the jack cylinder is completely loosened.

* During stressing, the operators should set protective boards at both sides of the strand to avoid accidents caused by the strand being flung.

* The operators should check the wear state of the inner wedge. |

| Knowledge Comment |

* The twisted PC steels tend to get loose near the cutting surface.

* If the PC steel was stressed from both sides, the cutting surface side might fly to the other side.

* Do not forget to manage and check during stressing. |

| Background |

This construction site was small one among the construction site of the pre-stressed concrete bridge. The site manager was appointed by considering the construction size and difficulty. This site manager had a 4 years career, so it was difficult to say he had enough experience. The site supervision was not adequate because there were not a transverse stressing standard and a checklist. Although the working foreman and his workers from the partner company had enough experience of this kind of operation, they did not consider seriously about the dangers during this operation because they treated the tool box meeting which was held after morning meeting and the risk prediction work halfheartedly. |

| Reason for Adding to DB |

The stressing is the most important part of the pre-stressed concrete operation, so it is very important not to make the same mistake again. |

| Scenario |

| Primary Scenario

|

Insufficient Analysis or Research, Insufficient Prior Research, Organizational Problems, Poor Management, Regular Operation, Erroneous Operation, Failure, Fracture/Damage, Bodily Harm, Harm to Physical Well-being, Bodily Harm, Death

|

|

| Number of Deaths |

1 |

| Number of Injuries |

0 |

| Multimedia Files |

Fig2.A brief image of accident

|

|

Fig3.An image of the stressing jack

|

| Notes |

Armored concrete has reinforced steels in the concrete to cover up the weakness that the concrete was strong in pressing but weak in stressing. The pre-stressed concrete is concrete which already contains pressure by using the PC steels instead of the reinforced steels. The stressing is the operation to generate compressing force. There are post-tensioning system and pre-tensioning system.

In this case, the post-tensioning beams were placed and combined by the transverse PC steels to construct a pre-stressed concrete bridge. The single strands were used as the transverse PC steels. |

| Field |

Civil Engineering

|

| Author |

IIDA, Tadayuki (P.S. Mitsubishi Construction Co., Ltd.)

OOTA, Yutaka (Fuji p.s Corporation)

KUNISHIMA, Masahiko (The University of Tokyo)

|