| Case Name |

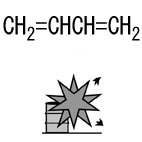

Explosion and fire at a butadiene cylinder exposed to the sunshine |

| Pictograph |

|

| Date |

August 14, 1994 |

| Place |

Yokkaichi, Mie, Japan |

| Location |

Chemical factory |

| Overview |

A 500 kg butadiene cylinder ruptured during use. It contained a small amount of popcorn polymer, which accelerated a polymerization reaction as a core, and was left under direct sunlight for 52 hours. So popcorn polymer was generated, the temperature rose, the safety valve was clogged by the polymer, pressure increased, the cylinder ruptured, and butadiene leaked and exploded.

Popcorn polymer: a polymer in an aggregate state like popcorn. Due to an increase in the volume compared with a monomer, the piping can get clogged and the container ruptures. Diolefins such as butadiene and chloroprene are readily polymerized by their temperature rises with coexisting oxygen even in a very small amount. |

| Incident |

A 500 kg cylinder of butadiene was stored. Butadiene in the cylinder exploded, while subdivision was being repeated. |

| Processing |

Research and development |

| Substance |

1,3-butadiene,Fig2 |

| Polybutadiene |

| Type of Accident |

Explosion, fire |

| Sequence |

1. A 500 kg cylinder was filled with butadiene.

2. It was moved to the location where it was used, and subdivisions were carried out many times.

3. The cylinder burst during use, butadiene in the cylinder spouted and the butadiene exploded and caused a fire. |

| Cause |

The temperature and pressure in the cylinder rose due to popcorn polymer generation of butadiene. Due to the pressure rise, the cylinder was destroyed, and butadiene spouted out. |

| Response |

Extinguishing activities by the Company's fire fighters and the public fire brigade. |

| Countermeasures |

1. Cleaning must be carried out so that any popcorn polymer should be left in the cylinder.

2. A smaller cylinder is required so that one cylinder should not be used for a long continuous period.

3. The education must be carried out on the danger of polymerization of butadiene. |

| Knowledge Comment |

Butadiene generates popcorn polymers, etc., and it is often connected with accidents. It is important to maintain basic storage conditions to prevent polymerization from occurring such as elimination of dissolved oxygen, addition of a polymerization inhibitor, avoiding high-temperature storage, etc. |

| Background |

Popcorn polymer generation is associated with butadiene, and it is important not to raise the temperature and to add a polymerization inhibitor. There was a small amount of popcorn polymer, which was at the core of polymerization, and it accelerated popcorn polymer generation, which was overlooked. In addition, the temperature rose because the cylinder was placed under direct sunlight. It is speculated that a deviation from basic butadiene handling was a factor, as indicated above. |

| Reason for Adding to DB |

Example of explosion caused due to popcorn polymer of butadiene |

| Scenario |

| Primary Scenario

|

Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Organizational Problems, Poor Management, Poor Operation Management, Carelessness, Insufficient Understanding, Insufficient Recognition of Risk, Usage, Transport/Storage, Wrong Storage Environment, Bad Event, Chemical Phenomenon, Abnormal Reaction, Secondary Damage, External Damage, Explosion, Loss to Organization, Economic Loss, Manetary Damage 30 million nyen

|

|

| Sources |

Fire and Disaster Management Agency, Fire and explosion of butadiene cylinder. Accident cases of dangerous materials. 1994, pp.338-341

|

| Physical Damage |

8.3 square meters of a building in which a fire occurred burned down. Three hoppers and two exhaust gas deodorizers partially burned. The windows of 32 buildings in the factory site and 85 nearby housing units were damaged. |

| Financial Cost |

¥ 31million. (Fire and Disaster Management Agency) |

| Multimedia Files |

Fig2.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

KOBAYASHI, Mitsuo (Office K)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|

|