| Case Name |

Fire of xylene remaining in solid piperazine separated in a centrifuge |

| Pictograph |

|

| Date |

May 22, 1998 |

| Place |

Kawasaki, Kanagawa, Japan |

| Location |

Chemical factory |

| Overview |

A fire involving burns occurred during piperazine crystal pulling-out work in the centrifugal separation process after synthesis of piperazine. Air flowed in because an operator failed to close the exhaust valve and the cover of the handhole. Then, a combustible gas-air mixture (ranges of flammability 1-7%) of xylene was formed. Although two polyethylene bags were put between the crystal and crystal receiving drum for insulation, measures were not taken to remove static electricity. A fire was caused by electric discharge of static electricity in the separation process. |

| Incident |

The operators received burns during pulling-out work at a centrifuge. Three operators separated piperazine crystallization liquid (a mixture of xylene and piperazine) into solid and liquid using the centrifuge. In addition, they were pulling out a cake of crystal from the centrifuge to a container placed beneath the centrifuge. The container was a steel drum can with two polyethylene bags (0.1 mm thick) inside the drum can. During pulling-out work, vapor rising from xylene with the piperazine was ignited by a static electricity spark. Then, two operators got burnt in their faces. Refer to Fig2. |

| Processing |

Manufacture |

| Individual Process |

Separation |

| Substance |

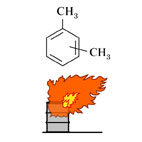

Xylene, Fig3 |

| Piperazine, Fig4 |

| Type of Accident |

Fire |

| Sequence |

On May 22nd, 1998, 08:05. Operator B turned on the switch of a scraping machine. Operating condition was checked by opening a handhole. The operator failed to close the handhole.

08:10. Operator A changed a filled container with a new one. He forgot to connect an earth to the new container and a roller.

08:15. Operators A and B observed the machine from the pull-out mouth of the centrifuge. At that time, ignition occurred, and flames struck the two operators. Fire extinguishing was carried out using a fire extinguisher, and electric power of the control panel was cut. |

| Cause |

An operator failed to close the exhaust valve and the handhole, so there was little sealing effect of the nitrogen gas. Therefore, a combustible gas-air mixture (ranges of flammability 1-7%) of xylene that remained in the piperazine crystal (about 5%) was generated in the centrifuge near the crystal pull-out mouth. In addition, static electricity generated in the separation process charged the piperazine crystal. AS the drum was insulated by two polyethylene bags, static electricity accumulated in the piperazine crystal. It reached the minimum ignition energy (1.2mJ) of the xylene and ignited. |

| Response |

The fire was extinguished using a fire extinguisher. The centrifuge was stopped. Control panel power supply in the control room was cut off. |

| Countermeasures |

1. Improving the pull-out container.

2. Improving earth connection.

3. Controlling and removing static electricity.

4. Intercepting air with nitrogen. The oxygen concentration in the pull-out container is kept at about 13-15%, which is under the lower combustible limit.

5. Prohibiting pulling-out work while the handhole is open.

6. Wearing protective masks.

7. Making a function check of earth connection.

8. Reviewing the manual and education. |

| Knowledge Comment |

This work was dangerous with a high probability of a combustible gas-air mixture forming and static electricity sparking. It was necessary to carry out strict safety management based on sufficient recognition of this point . |

| Background |

During centrifugal separation, liquid cannot be perfectly separated, and solvent components exist in the separated cake. The workers should have understood that xylene vapor will rise and make a combustible gas-air mixture.

The specific causes were: 1) There was no earth connection in spite of electrically isolated. 2) The operator forgot to close the exhaust valve. 3) The operator forgot to close the handhole, either. |

| Incidental Discussion |

There are many accidents related to static electricity. It must not be forgotten that static electricity is generated even at an unsuspected place.

Countermeasures are really fundamental. It was a basic problem that managers and staff did not consider safety sufficiently. |

| Reason for Adding to DB |

Example of fire caused due to inadequate nitrogen gas seal |

| Scenario |

| Primary Scenario

|

Organizational Problems, Poor Management, Slackness of Management, Carelessness, Insufficient Understanding, Insufficient Recognition of Risk, Poor Value Perception, Poor Safety Awareness, Inadequate Risk Recognition, Malicious Act, Rule Violation, Safety Rule Violation, Planning and Design, Poor Planning, Poor Design, Regular Movement, Careless Movement, Not take the grounding, Secondary Damage, External Damage, Explosion, Bodily Harm, Injury, 2 person injured

|

|

| Sources |

Fire and Disaster Management Agency. Major cases of accidents. Centrifuge fire in an amine factory. Accident cases of dangerous material. pp.25, 300-301.

High Pressure Gas Safety Inst. of Japan. High-pressure gas protection overview. p.151(2000).

Kawasaki City Fire fighting station. Prevention division. Fumio Itakura. Case of fire caused by static electricity. Dangerous object accident case seminar. pp.21-36(1999).

Kawasaki City Fire fighting station. Prevention division. Peace section. Centrifuge fire. Material of the Kawasaki City complex safety countermeasure committee (1998)

|

| Number of Injuries |

2 |

| Physical Damage |

Polypropylene filter cloth with a stainless wire mesh, polyethylene filter cloth and a bag in a drum of a centrifuge were damaged by fire. |

| Financial Cost |

¥ 90,000. (Accident cases of dangerous materials) (Material of the Kawasaki City complex safety countermeasure committee) |

| Multimedia Files |

Fig2.Sketch of site of accident

|

|

Fig3.Chemical formula

|

|

Fig4.Chemical formula

|

| Field |

Chemicals and Plants

|

| Author |

DOBASHI, Ritsu (School of Engineering, The University of Tokyo)

TAMURA, Masamitsu (Center for Risk Management and Safety Sciences, Yokohama National University)

|