| Case Name |

Hibiya Line Derailment Accident |

| Pictograph |

|

| Date |

March 8, 2000 |

| Place |

Meguro, Tokyo, Japan |

| Location |

Naka-Meguro on the Teito Rapid Transit Authority's (TRTA) Hibiya line |

| Overview |

Near the Naka-Meguro Station on the TRTA's Hibiya line in Tokyo, the last car of an 8-car subway train bound for Kikuna from Kitasenju derailed on a curve. The 5th and 6th cars of oncoming 8-car train bound for Takenotsuka from Naka-Meguro hit the derailed car. The Hibiya line had 3.5m of track-center distance between the inbound and the outbound tracks. The accident claimed 5 lives and 63 injuries. |

| Incident |

Near the Naka-Meguro Station on the TRTA's Hibiya line in Tokyo, the last car of an 8-car subway train bound for Kikuna from Kitasenju derailed on a curve. The 5th and 6th cars of oncoming 8-car train bound for Takenotsuka from Naka-Meguro hit the derailed car. The accident claimed 5 lives and 63 injuries. |

| Sequence |

At around 9:00 am on March 8, 2000, the 8-car subway train A861S bound for Kikuna from Kitasenju was carrying approximately 100 passengers on its way to the Naka-Meguro Station on the TRTA's outbound Hibiya line (A line) in Tokyo.

At 9:01 am, two wheels of the last car (carrying 6 passengers) of the subway train detailed 150m before the Naka-Meguro Station when it was traveling at approximately 12 - 13km/h on a sloped (35/1,000) transition curve (between curve and straight lines) following a left curve of radius 160m. The derailed train stopped on the railway sleepers at the branching of the setoff equipment (for bringing a maintenance train to the main line) located 50m away from the derailed point. The derailed train was hit by the oncoming Tobu Railway's 8-car train B801T bound for Takenotsuka from Naka-Meguro carrying 1,000 passenger, which was traveling on the inbound line (B line) that had a 3.5m track-center distance from the outbound line (A line).

The collision badly damaged the 8th car of the A861S as well as the 5th and the 6th cars (each carrying 125 passengers) of the B801T.

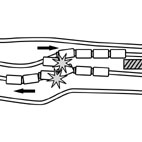

Figure 1 illustrates details of the accident.

The accident killed 5 and injured 63 people.

After the collision, the A861S operators activated the emergency brake and stopped the train. The B801T stopped traveling as the emergency brake was automatically activated in response to the rupture of the brake pipe located between the 5th and the 6th cars.

The 8th car of the A861S had its right side in the traveling direction damaged severely from its front towards the center door area. The 5th car of the B801T had its right front area damaged and its right side heavily scratched in the center door area towards the end of the car. The 6th car of the B801T had its right side damaged severely from its front towards the first door area. The collision also left scratch marks in the rear area of the 4th car, the center area of the 7th car and the right side of the 8th car. The electric cable and the brake pipe were also damaged on the right side at the connection between the 5th and the 6th cars.

The outer track on the curve where the wheels derailed had 7m-long skid marks made by the flange starting at the 18.333 km point and shorter marks at the 1m-point from where the wheels derailed. The inner track on the curve also had small marks.

The outer wheel tread and the flange had marks shown in Figure 1 within the 1.3m-radius of the first axle. |

| Cause |

The derailment occurred at the entrance to a transition curve following a sharp left curve, where moderate torsion of the track surface (within the limits allowed by the safety standard) causes weight imbalance in the train wheels on both sides (weight decrease in the right wheels and lateral force increase, see Figure 3a). It is believed that this and other factors increased the derailment coefficient in the right wheel of the 8th car's first axle, causing the wheels to run over the track before actually jumping the track (Figure 3b). Derailment of this sort is called the "run-over-the-track" derailment.

The investigation made the following discoveries and concluded that weight imbalance in the first-axle train wheels contributed to the derailment:

(1) The production measurement showed the first-axle and the fourth-axle train wheels supported less weight of the train. The weight of the train was not distributed evenly.

(2) The railways did not perform maintenance of weight balance after the railcar was put in service.

(3) Other railcars of the same model (Model 03) showed the same weight imbalance in the train wheels.

In addition to the existing weight imbalance in the model, the following factors worsened the weight imbalance in the train wheels (weight decrease in the right wheels and lateral force increase). The current design and maintenance do not consider some of them to be defects, and some pose difficulty in proper maintenance. These factors may or may not contribute to train derailment.

- The coefficient of friction between wheels and the track increased when the train traveled on the curve, and this increase resulted in an increase of lateral force.

- The characteristics of the axle spring and the stiffness of the air suspension that damps out the motions of the railcar contributed to an increase in lateral force and a decrease in weight in the right wheels.

- Lateral force increased because of the shape of the wheel tread in contact with the particular surface of the track that was shaved to remove scratches and dents. |

| Response |

On March 8, the day when the accident happened, the Accident Investigation Commission (Chairman: Masakazu Iguchi, Professor, Emeritus at the University of Tokyo) submitted the investigation report to the Transport Ministry of Japan at its first meeting. The commission agreed on establishing a working group and necessary measures to be taken before reopening the service:

(1) All railcars of the accident model must have a complete overhaul on its air suspension and bogie.

(2) A derailment prevention guard (rail or angle steel installed on the inner side of a track to prevent derailment) must be installed at the derailment point.

(3) The travel speed must be reduced to 15 km/h or less near the derailment point.

At the second meeting held on March 16, the following measures were imposed on all railways including transit authorities that provide passenger services to prevent similar accidents from happening.

For all curves of 200m radius or less:

(1) A transition curve that follows a curve must have a derailment prevention guard, a derailment prevention rail or a safety rail installed.

(2) For other sections, a derailment prevention guard, a derailment prevention rail or a safety rail must be installed. The installation will start from sections that have higher risk of derailment after assessing the conditions including the gradient ratio and radius of curvature.

The Transport Ministry ordered the installation to applicable railways. |

| Countermeasures |

On October 30, the TRTA announced the derailment prevention measures in response to the advisory report given by the Accidents Investigation Commission of the Transport Ministry. The TRTA completed adjusting the wheel weight ratio (indicating the balance of weight in the train wheels on both sides) to within 15% or less for all Model-03 railcars allocated to the Hibiya line by June and for 90% of all Model-03 railcars on all lines by October 10. In 2001 the TRTA set the stricter guidelines and adjusted the wheel weight ratio to be 10% or less. It also installed 5 new control systems (40 - 50 million yen per a system).

The flanges were angles were set to 60 degrees for all railcars in service on the Hibiya, Chiyoda and Yuraku-cho lines at the time of the accident, and TRTA changed this angle to 70 degrees for railcars on the Hibiya line by November 9, Chiyoda and Yuraku-cho lines by September 2001. The railcars in service on other lines originally had flanges angles of 67- 70 degrees.

The TRTA's periodic shaving operation will remove scratches and dents to maintain the original surface and shape of track on sharp curves. The TRTA Railway commissioned the Technical Research Institute to determine the optimal track shape.

The TRTA lengthened the transition curve at the derailment site by 10m from 30m to 40m. |

| Knowledge Comment |

A combination of various factors may cause an accident. In order to determine the actual cause of each accident, it is essential to comprehensively study every factor that may have caused the accident and estimate the safety factor. Before preventing recurrence of accidents, investigators must understand circumstances and the series of events that led to the accident. Note that the safety factor account for imperfections in material, flaws in assembly, material degradation, and uncertainty in load estimates. Periodical maintenance must prevent changes in shape, which occurs due to wear, because such changes lower the safety factor. |

| Background |

Before this Hibiya line accident, the railways had been testing the railcars for their wheel weight and lateral force whenever some change, such as new models, new lines and an increase in travel speed on a line, is made to the service to ensure safety. Such a test was conducted on the first axle under the expected travel speed. However, the field study of the accident found that the derailment coefficient is greater in wheels that have smaller weight ratio when the railcar travels slowly on a transition curve following a sharp curve. The accident proved the need for testing all axles.

For the wheel weight imbalance, which was another cause of the accident, the railways' production process did not include testing and adjustment of wheel weight balance at factories. (In response to the advisory by the investigation commission, all railways started testing wheel weight for all wheels and axles within 2 years from the accident.) |

| Incidental Discussion |

The Accident Investigation Commission conducted the accident investigation including field study and analysis from the day when the accident happened until October 26 of the same year. In order to determine the direct cause of the derailment, the investigators recreated the accident as accurately as possible at the accident site and examined the railcar's motion. The investigators also ran a simulation to analyze various factors and determine the extent of their contributions to the derailment.

The Commission estimated the safety factor based on the derailment coefficient calculated by using the formula: Estimated ratio of derailment coefficient = Derailment coefficient limit / Estimated formula of wheel weight and lateral force. Estimated ratio of derailment coefficient represents the ratio between the maximum lateral force and the minimum wheel weight. The investigators analyzed railcars' motion on curve as well as various factors that influence wheel weight and lateral force to obtain the safety factor.

In light of this tragic accident, the Accident Investigation Commission announced the following recommendations at its fifth meeting held on July 31, 2001.

(1) To facilitate quick investigation upon an accident, accumulation of accident-related know-how and data, and continuity of accident investigation, it is necessary to establish a permanent and specialized investigation system that can conduct specialized accident investigations along with a system to prevent recurrence of accidents due to similar causes. (This gave concrete impetus for official establishment of the Aircraft and Railway Accident Investigation Commission, an independent standing commission of the Ministry of Land.)

(2) To assure smooth investigations of accidents, the Commission must collect and hold accident-related data and items. (The commission investigators arrived at the accident site after the police collected evidences, which had been always the case in accident investigation. When an accident happens, the investigation of criminal negligence is given priority over investigation of accident causes in Japan, which makes it difficult for the investigation commission to determine the direct causes and help preventing recurrence of accidents. In this accident, the commission investigators were able to obtain the evidences because they were also crime laboratory officers of the police. )

(3) Fundamental R&D into railway accidents must be promoted. |

| Scenario |

| Primary Scenario

|

Unknown Cause, Occurrence of Unknown Phenomenon, Poor Value Perception, Poor Safety Awareness, Usage, Maintenance/Repair, Malicious Act, Rule Violation, Failure, Fracture/Damage, Bodily Harm, Death

|

|

| Sources |

[1] Railway Accidents Investigation Commission (2000) Derailment at the Teito Rapid Transit Authority's Naka-Meguro Station on the Hibiya Line, Japan, October 26, 2000, The Ministry of Transport of Japan.

[2] NEWS FILE (Railway Topics), Tetsudo Journal (Railway Journal), February 2002,

http://www.railfan.ne.jp/rj/main/news_102x.html

|

| Number of Deaths |

5 |

| Number of Injuries |

63 |

| Multimedia Files |

Figure1.Schematic Illustration of Accident Site [1]

|

|

Figure2.Derailment Marks [1] (Modified)

|

|

Figure 3."Ran-Over-the-Track" Derailment

|

| Field |

Mechanical Engineering

|

| Author |

NAKAO, Masayuki (Institute of Engineering Innovation, School of Engineering, The University of Tokyo)

|

|